In today’s competitive market, your brand must consistently deliver high-quality products efficiently and cost-effectively.

Products that are too complicated or overly reliant on hard-to-source materials are more prone to defects and cost overages. Fortunately, the design for manufacturing (DFM) framework can help you save time and money while preserving product quality. This approach also accelerates time to market.

Here’s a closer look at the foundational design for manufacturing principles and how Eric Scott takes a collaborative approach to DFM.

Understanding DFM Principles

The design for manufacturing methodology focuses on designing products that promote a smooth and efficient manufacturing process.

DFM moves past the question “Will it work?” and instead considers factors like ease of production, cost-effectiveness, and simplicity of assembly. Your business can identify potential challenges and inefficiencies early by considering how a product will be made before production begins.

With that in mind, here are the primary DFM principles you should be familiar with:

Simplification

The design for manufacturing framework identifies ways to simplify a product’s design. The goal is to minimize the number of parts required and use standardized components so manufacturers can streamline assembly processes. A simpler design also decreases the likelihood of errors and reduces labor costs.

What’s more, simplifying your product can facilitate maintenance and improve product reliability. For example, designing a product with fewer fasteners or snap-fit features can significantly reduce assembly time and costs.

Cost Reduction

The design for manufacturing methodology also strives to reduce your production costs. It achieves this by addressing both manufacturing and material-related expenses.

By optimizing designs for manufacturability, your business can reduce its material usage and waste. As an added benefit, products that are easier to produce and assemble can also be brought to market sooner.

Additionally, the DFM framework allows manufacturers to identify potential manufacturing issues earlier. In turn, their production partners can make design modifications that prevent costly errors during production.

Material Selection

Sustainability is another factor in material selection. Eric Scott maintains an extensive network of suppliers to ensure that our production materials are sustainably and ethically sourced.

Process Optimization

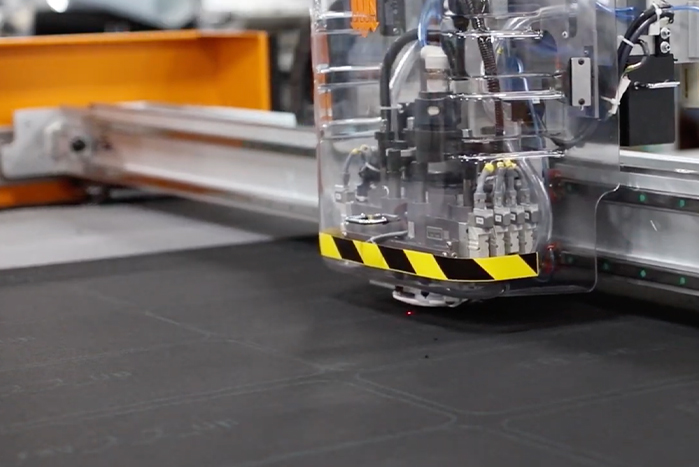

Tooling represents one of the major costs associated with manufacturing. If your production partner has to develop new tools or retrofit their machinery to create your product, your manufacturing costs will be higher.

The DFM framework focuses on optimizing designs to align with existing manufacturing capabilities and processes. The goal is to avoid the need for retooling, thereby decreasing costs and production time.

Testing and Quality Control

About one-third of customers stop supporting a brand after a single bad experience. Quality control and testing help ensure that your customers have a great experience with your new product.

The DFM methodology incorporates testing and quality control considerations into the design phase to preserve product reliability and performance. DFM encourages the design of products that are easy to test and inspect.

Eric Scott’s Collaborative Approach to DFM

Eric Scott prioritizes close collaboration with clients to ensure that their product designs align with our manufacturing capabilities. We’ll work closely with you from the initial concept phase to provide insights into how design choices impact cost, efficiency, and time to market.

For example, our DFM experts might suggest minor design modifications, such as standardizing component sizes or selecting materials that are easy to work with. These subtle changes will maintain the spirit of your design while cutting costs and guaranteeing manufacturing efficiency.

Real-World Success Stories: How One Brand Transformed Its Leather Goods Production

Expanding a premium leather goods brand comes with its challenges—rising costs, production limitations, and sourcing high-quality materials. Facing these hurdles, one company partnered with Eric Scott to streamline operations, reduce costs, and scale without sacrificing craftsmanship. The results? Lower production costs, increased capacity, and faster time-to-market.

Discover how this partnership reshaped their business and set them up for long-term success.

👉 Read the full case study here

Partner With the DFM Experts at Eric Scott

Design for manufacturing principles can reduce the cost and complexity of producing your products at scale. Eric Scott excels at applying the DFM framework to soft goods, which enables us to align your efficiency and budgetary needs while delivering a superior-quality product.

Contact us to learn more about how our DFM expertise can optimize your production process.