At Eric Scott, we specialize in turning innovative concepts into tangible, high-quality soft goods.

Our time-tested contract manufacturing process ensures a seamless journey from initial idea to final creation. Our approach to soft goods manufacturing combines global sourcing strategies and U.S. production processes to yield superior products at a reasonable cost.

Familiarizing yourself with our contract manufacturing process will promote a more fruitful collaborative journey as we bring your vision to life. Here’s how we move from concept to creation.

The Contract Manufacturing Process

Initial Consultation and Vision Development

The initial consultation is where our design experts get to know your brand and product idea. Our designers will use their decades of combined experience to ask targeted questions and better understand the inspiration behind your vision. We want to know your “why” so we can effectively capture the spirit and purpose of your product.

We’ll establish clear communication expectations at the outset. This involves identifying your preferred point of contact and the team member who will lead the design process. Maintaining open communication channels from day one helps prevent delays and makes collaboration more productive.

For instance, suppose that a client wants to launch a new line of custom leather accessories. We would explore their brand aesthetics, functional needs, and target audience to propose design elements and material selections that perfectly match their vision. Then we will present our design concepts to you, providing visuals and explanations to ensure alignment and gather feedback to adjust where needed.

We will then present and explain our visual design concepts to you and gather your feedback in order to make any necessary adjustments.

Design and Prototyping

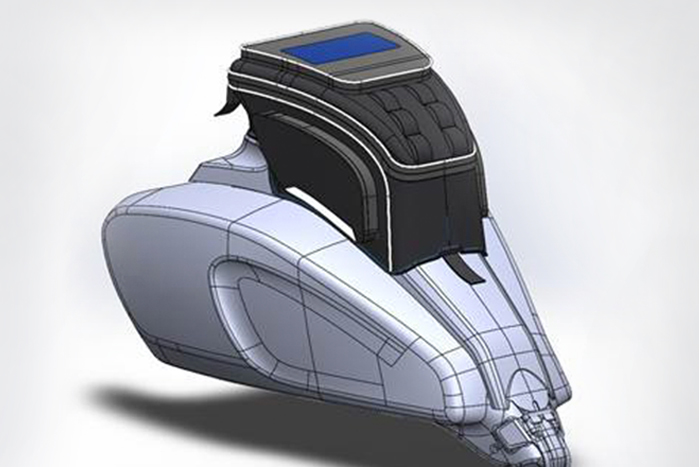

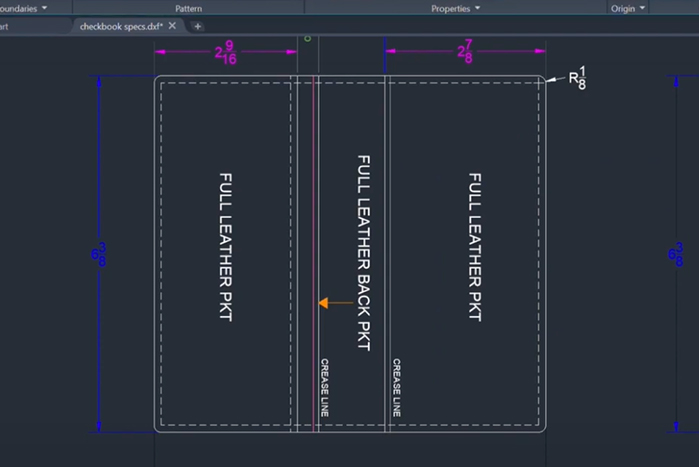

Once we have a clearly defined vision, our design and engineering team employs advanced computer-aided design (CAD) and 3D modeling tools to create detailed product designs.

These tools give you an opportunity to visualize your product before the prototyping stage. You’ll work with our team to make adjustments and fine-tune the design.

Once you’re satisfied with the 3D model, we’ll move on to prototyping and the pre-production review. Our team will create a prototype, or physical model, so you can inspect the product and make additional recommendations. Our design and engineering team will use this model to ensure that each design is optimized for efficient production. Eric Scott embraces design for manufacturing (DFM) principles to simplify products and expedite assembly. The goal is to minimize costs and production time while meeting our clients’ high quality standards.

Sourcing and Manufacturing

Eric Scott combines the best of domestic craftsmanship with global sourcing to provide high-quality soft goods at competitive prices.

We source premium leather and fabric from our network of trusted suppliers. Our industry connections and diverse supply chain also enable us to source vinyl, accessory items, and hardware cost-effectively.

We’re cognizant of the potential environmental impacts of sourcing leather and fabric. In light of this, we adhere to stringent sustainability and ethical standards to offer a transparent contract manufacturing process your brand can be proud of.

The centralized location of Eric Scott further promotes sustainability and ethical sourcing. Our leadership team works tirelessly to improve our supply networks and eliminate waste from our manufacturing process.

Quality Assurance and Delivery

Our team has worked for decades to establish an impeccable reputation as an industry leader in the soft goods sector. The quality of our products has played a key role in achieving this distinction.

Quality is ingrained in every step of our manufacturing process. We’ll conduct rigorous testing and inspection at each stage of production to ensure that the final product meets or exceeds your expectations. The end result is high-quality soft goods your customers will love.

Our central location in Ste. Genevieve and strong logistics partnerships allow us to consistently provide on-time deliveries. Additionally, our logistics network enables us to accommodate tight deadlines and rapid turnaround requests.

Start Your Contract Manufacturing Journey With Eric Scott

Contract manufacturing represents one of the most efficient and cost-effective options for bringing your product vision to life. However, it’s essential that you choose a partner that balances cost savings with quality and efficiency.

Eric Scott has a time-tested production workflow and a client-centric service team that’s eager to surpass your expectations.

Do you have an exciting vision that you’re ready to turn into a market-ready product? Request a product quote today to start your product journey with Eric Scott.